- Viscosity [mPa*s] : < 20

- Appr. Mw [kDa] : < 75

- G/M Ratio : ≤ 1

- Endotoxins [EU/g] : ≤ 100

- Total viable count [cfu/g] : ≤ 100

PRONOVA® UltraPure or Sterile Sodium Alginates

NovaMatrix® is the world’s leading producer of medical grade Sodium Alginates: we have been manufacturing UltraPure Alginates since 1988. PRONOVA® UltraPure and PRONOVA® Sterile sodium alginates are our flagship products.

PRONOVA® alginates, a solid track record of safety and efficacy –

PRONOVA® alginates are very versatile, well-characterized, safe and bio-compatible marine biopolymers. They have been purified for biomedical and pharmaceutical applications. PRONOVA® UltraPure Alginates have been used in commercial medical applications for over two decades.

Chemistry

Alginate is a naturally-occurring biopolymer extracted from brown seaweed.

In contrast to most other polysaccharides, Alginates can form hydrogels at constant temperature, in presence of divalent cations such as Ca2+, Ba2+ or Sr2+. This unique property is particularly useful in applications involving fragile materials like cells or tissue with low tolerance for higher temperatures. For more information, please click on the hyperlink PRONOVA® Alginates – Hydrogels formation and fill in a simple contact form.

Properties

- Form 3-dimentional hydrogel matrixes in presence of divalent cations

• Ability to form beads to entrap cells and therapeutic actives

• Ability to form 3D scaffolds, foams and other structures - Cell affinity

• Cell entrapment in alginate matrixes

• Controlled viscosity and gelation based on alginate type and cation selection Wide range of viscosities and gel strengths available - Cold / hot water solubility

- Rheology modification

- Suspending agent

- Film forming

- Naturally-occurring biopolymer with 20+ years in commercial applications

• Safe, biocompatible - Ultrapure, for medical use

- Long shelf-life: from 3 to 5 years, depending on the product

Safety and toxicology

The safety and toxicology profile of PRONOVA® UltraPure sodium alginate is described in a Drug Master File (DMF) submitted to the US FDA. If you would like to learn more about the Safety and toxicology of PRONOVA® UltraPure Alginates, please click on the hyperlink and fill in a simple contact form.

Applications

- Encapsulation of living cells and therapeutic proteins for cell therapy and advanced drug delivery

- Bone putty binder for tissue engineering and reconstruction

- Cryoprotection for cell and tissue

- 3D bioprinting

- Foams and cell tissue scaffolds

- Cell culture

- Hydrogels

- Advanced drug delivery

- Implants

- Anti-adhesion

- Wound management

- Medical device coating, etc.

Product selection

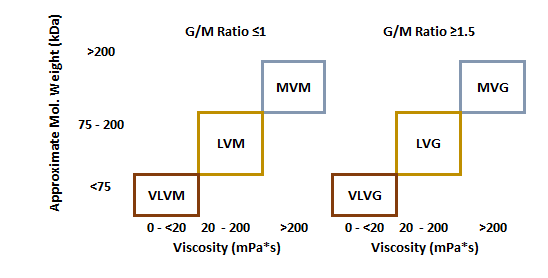

PRONOVA® UltraPure Alginates – PRONOVA® UP Product Table

All our PRONOVA® UltraPure Alginates have ≤ 100 EU / g endotoxins specifications as well as ≤ 100 cfu /g total viable count specifications.

We have the ability to supply PRONOVA® UltraPure Alginates at lower endotoxins specifications, as well as tailor-made grades. Please connect with us for more information.

The shelf-life of PRONOVA® UltraPure Alginates varies by grade. If you would like to learn more about PRONOVA® Alginates product shelf-life, please click on the hyperlink and fill in a simple contact form.

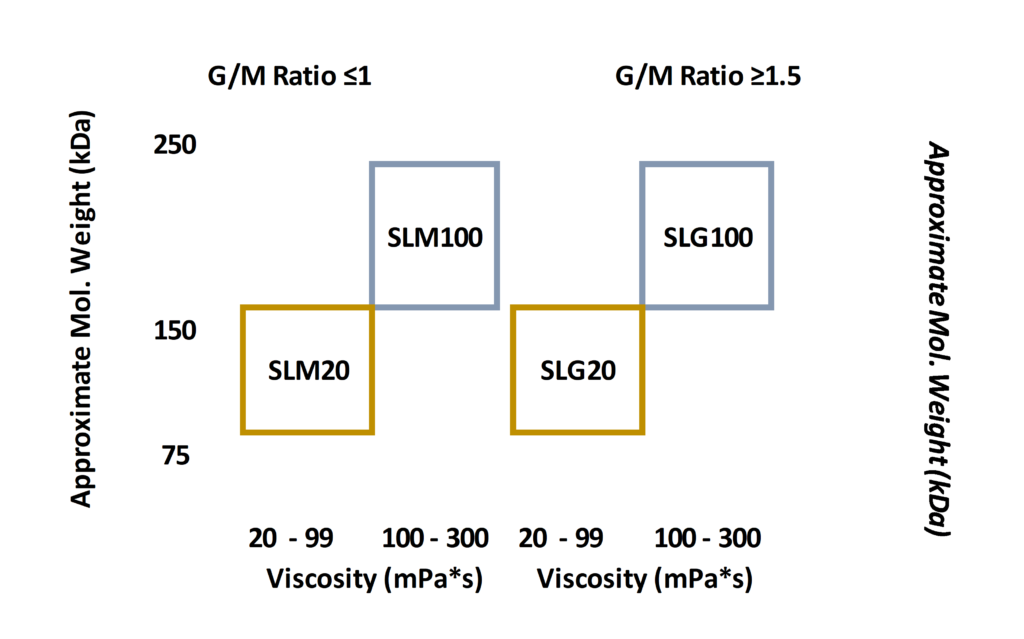

PRONOVA® Sterile Alginates – PRONOVA® S Product Table

All our PRONOVA® Sterile Alginates have ≤ 100 EU / g endotoxins specifications.

We have the ability to supply PRONOVA® Sterile Alginates at lower endotoxins specifications, as well as tailor-made grades. Please connect with us for more information.

The shelf-life of PRONOVA® Sterile Alginates varies by grade. If you would like to learn more about PRONOVA® Alginates product shelf-life, please click on the hyperlink and fill in a simple contact form.

Alginate is a linear polysaccharide consisting of (1,4)-linked b-D-mannuronate (M) and its C-5 epimer α-L-guluronate (G).

The monomers can appear in homopolymeric blocks of consecutive G-residues (G-blocks), consecutive M-residues (M-blocks), alternating M and G-residues (MG-blocks) or randomly organized blocks.

PRONOVA UP VLVM

PRONOVA UP LVM

- Viscosity [mPa*s] : 20-200

- Appr. Mw [kDa] : 75-200

- G/M Ratio : ≤ 1

- Endotoxins [EU/g] : ≤ 100

- Total viable count [cfu/g] : ≤ 100

PRONOVA UP MVM

- Viscosity [mPa*s] > 200

- Appr. Mw [kDa] : > 200

- G/M Ratio : ≤ 1

- Endotoxins [EU/g] : ≤ 100

- Total viable count [cfu/g] : ≤ 100

PRONOVA UP VLVG

- Viscosity [mPa*s] : < 20

- Appr. Mw [kDa] : < 75

- G/M Ratio : ≥ 1.5

- Endotoxins [EU/g] : ≤ 100

- Total viable count [cfu/g] : ≤ 100

PRONOVA UP LVG

- Viscosity [mPa*s] : 20-200

- Appr. Mw [kDa] : 75-200

- G/M Ratio : ≥ 1.5

- Endotoxins [EU/g] : ≤ 100

- Total viable count [cfu/g] : ≤ 100

PRONOVA UP MVG

- Viscosity [mPa*s] : > 200

- Appr. Mw [kDa] : > 200

- G/M Ratio : ≥ 1.5

- Endotoxins [EU/g] : ≤ 100

- Total viable count [cfu/g] : ≤ 100

Product

Viscosity [mPa*s]

Appr. Mw [kDa]

G/M Ratio

Endotoxins [EU/g]

Total viable count [cfu/g]

PRONOVA SLM20

- Viscosity [mPa*s] : 20-99

- Appr. Mw [kDa] : 75-150

- G/M Ratio : ≤ 1

- Endotoxins [EU/g] : ≤ 100

- Total viable count [cfu/g] : Sterile

PRONOVA SLM100

- Viscosity [mPa*s] : 100-300

- Appr. Mw [kDa] : 150-250

- G/M Ratio : ≤ 1

- Endotoxins [EU/g] : ≤ 100

- Total viable count [cfu/g] : Sterile

PRONOVA SLG20

- Viscosity [mPa*s] : 20-99

- Appr. Mw [kDa] : 75-150

- G/M Ratio : ≥ 1.5

- Endotoxins [EU/g] : ≤ 100

- Total viable count [cfu/g] : Sterile

PRONOVA SLG100

- Viscosity [mPa*s] : 100-300

- Appr. Mw [kDa] : 150-250

- G/M Ratio : ≥ 1

- Endotoxins [EU/g] : ≤ 100

- Total viable count [cfu/g] : Sterile

Product

Viscosity [mPa*s]

Appr. Mw [kDa]

G/M Ratio

Endotoxins [EU/g]

Total viable count [cfu/g]

NOVATACH MVG GRGDSP (GRGDSP-coupled high G-content high Mw alginate)

- G/M Ratio : ≥ 1.5

NOVATACH VLVG 4GRGDSP (GRGDSP-coupled high G-content low Mw alginate)

- G/M Ratio : ≥ 1.5

NOVATACH LVM GRGDSP (GRGDSP-coupled alginate)

- G/M Ratio : ≤ 1

NOVATACH G VAPG (VAPG-coupled alginate)

- G/M Ratio : ≥ 1.5

NOVATACH M REDV (REDV-coupled alginate)

- G/M Ratio : ≤ 1